Guide Navigation

Introduction to Picture Framing & Matting

Designing Your Picture Frames and Mats

Color Selection

Matboard Types

Frame Types

Mat styles

Glass types

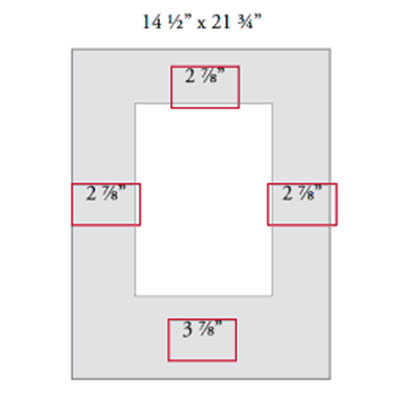

Measuring and Sizing Picture Frames and Mats

Mats

Frames

Costs of Picture Framing

DIY Picture Frames

Mat Cutting

Cutting mat board sheet to size

- Making the Most of a 32 x 40 Sheet

- Trimming Mat Board to Size

- Trimming Mat Board to Size with Straight Edge

- Trimming Mat Board to Size with Compact

- Trimming Mat Board to Size with Simplex

- Mat Cutting

- Cutting Single Mat Using a Straight Edge

- Cutting a Single Mat With a Simplex-Basics

- Cutting a single mat with a simplex-detailed

- Cutting a double mat

- Cutting a double mat- detailed professional version

- The professional framers secret for cutting a double mat

- How to measure and cut a double mat,

- Cutting a stepped corner mat – basics

- Cutting stepped corner mats – detailed

- Offset (stepped) corner mat

Mat Cutter Choices

Mat Cutting Help, Troubleshooting and FAQs

- Slip sheets

- The importance of using a slip sheet when cutting

- The importance of using a backing sheet

- Why am I getting a ragged cut?

- How to avoid rough or ragged edges when cutting mats

- Dealing with inconsistencies in the bevel edges

- Adjusting your mat cutter for proper blade depth

- The importance of proper blade depth

- Why am I getting a hook in the corners or curve in the bevel cut?

- How come I don't cut all the way through the mat board?

- How to conquer overcuts and undercuts?

- Dealing with overcuts and undercuts

- Why am I getting overcuts in the corners?

- Why are my mats not coming out square?

- Why is my bevel cut going the wrong way?

- How to cut left handed

- How to cut a 40" sheet of mat board on the 32" compact mat cutter

- Is using production stops the fool proof way to get perfect mats?

- Tips for working with production stops on your mat cutter

- Basic mat cutter maintenance

Mounting Your Artwork

Methods of Mounting

- Mounting your artwork

- Grappling with conservation and archival mounting concerns

- Supporting Artwork

- Hinge mounting T, V and S methods

- A simple method to a T-hinge mount

- Trapping methods

- Permanent mounting

- Wet mounting

- Pressure sensitive adhesive mounting

- How to mount artwork using positionable mounting adhesive (PMA)

- Spray adhesives

Glazing with Glass and Plastic

Securing or Fitting your Artwork in a Picture Frame

Finishing Your Artwork

INTRODUCTION

Picture framing and matting can be an easy, quick process, but also can be a longer, elaborate process as well. Depending on the types of outcomes you're wanting to achieve, there are a few steps, or many, that you will need to know and follow to obtain the best results. The sections in Guide Navigation will present to you all the in's and out's of picture framing, mat cutting, and more. Click a section now to dive in!